Tube Squaring and Sanding

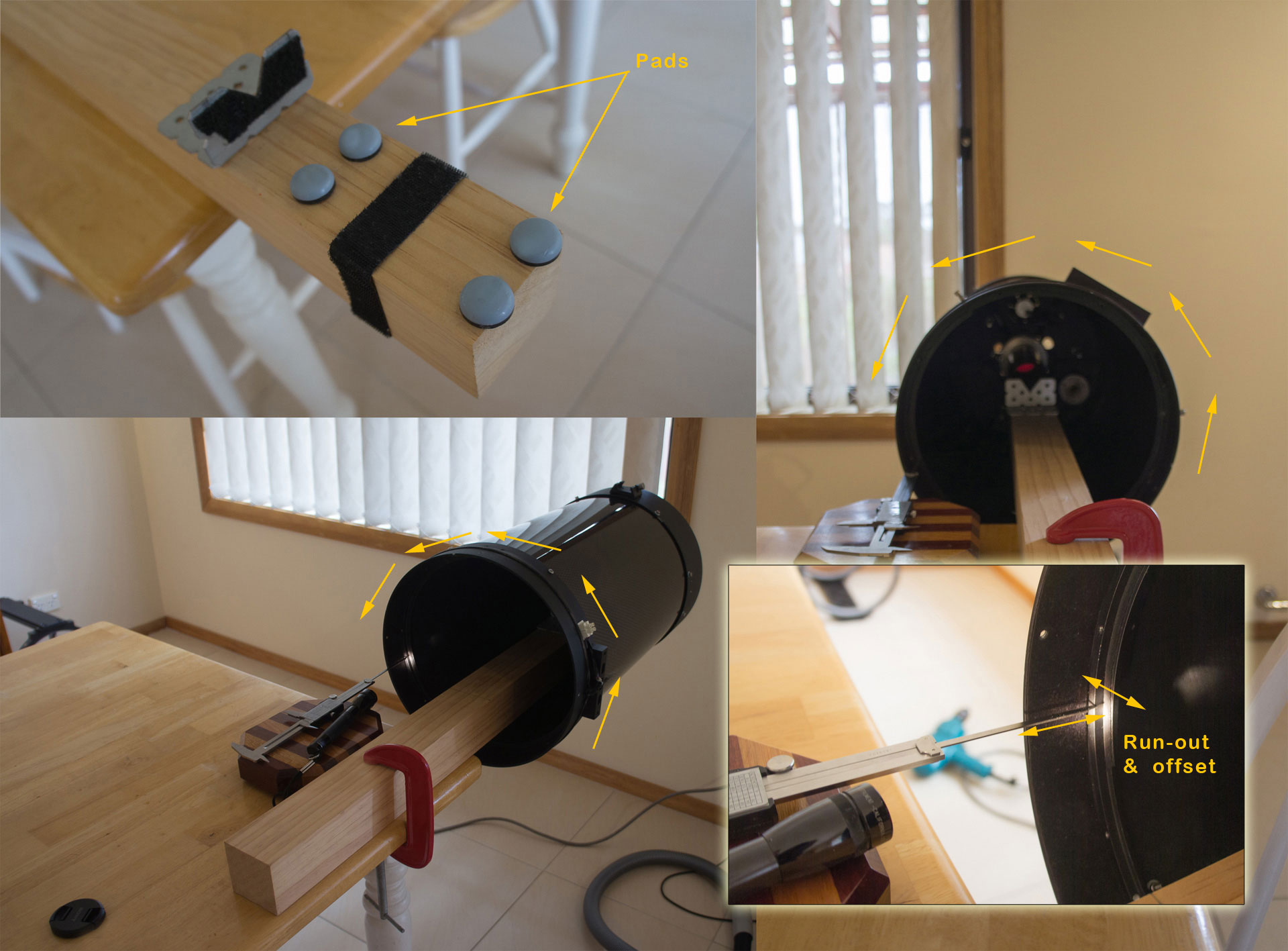

A Jig is used to spin the tube on its baffle and check the run-out accurately. First the primary mirror is removed, so the tube is empty. The baffle tube is placed on a piece of wood on four little plastic pads slightly greased so we can spin the tube rigidly on its baffle. The whole tube is balanced. All that is needed is to rotate it slowly and check the 'wobbling' at the front.

This is a very accurate way of checking if the tube is skewed in the primary cell casting. By using the end bit of a caliper and touching the machined face of the corrector cell one can detect 'high' spots then sand the opposite end of the tube to straigten it until there is no run-out left.

After completion this guarantees that the optical axis of the corrector will be very close to the mechanical axis of the telescope baffle tube and focusing arm tube . It helps greatly with the centering of the secondary as it is centered in the corrector lens and in turn the corrector is centered in the corrector cell. So getting the centering of the corrector cell right is the first step. An offset corrector will likely cause astigmatism.

Also an offset secondary will introduce field problems at prime focus. An offset secondary cell will cause field tilt when the hyperstar is fitted in the front of the scope. Compensating by tilting the hyperstar will introduce flaring in the stars airy pattern.